Application Deployment

Tailored for Industry-Specific Scenarios, RONDS Introduces the “1+N+X” Intelligent Maintenance Solutions

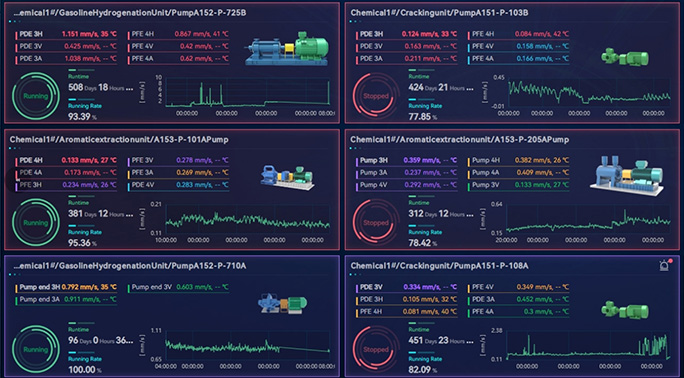

Built on a unified digital platform("1"), the solution integrates diverse intelligent hardware and interfaces("N") to create a unified, full-spectrum data sensing system. This foundation supports a wide range of smart maintenance applications across industries("X"), and is designed for continuous expansion—unlocking limitless potential for digital transformation.

-

Ronds intelligent operation and maintenance platform, with "automated equipment inspection, intelligent status judgment, and precise equipment operation and maintenance" as its core content, transforms from the traditional preventive maintenance system to predictive maintenance and predictive maintenance, realizes safe operation of equipment, reduces operation and maintenance costs, improves overall efficiency, improves work experience, and effectively promotes the intelligent transformation of enterprises.

-

-

RW606(M) Wireless Tri-axial Vibration,Temperature and Speed Sensor

RW606(M) Wireless Tri-axial Vibration,Temperature and Speed Sensor-

Frequency range: Piezo(Z) direction:2Hz~20KHz,±3dB; MEMS(X,Y) directions: 2Hz~1kHz,±3dB

-

Waveform length: Piezo Z Maximal 256K; Mems X,Y Maximal 16K

Learn More

New Product Release

New Product Release -

-

RH103(T) Wired Vibration Temperature Sensor

RH103(T) Wired Vibration Temperature Sensor-

Frequency range:0.4~15KHz(±3dB)

-

Sensitivity:100mv/g

Learn More

New Product Release

New Product Release -

-

RH570 Wireless Data Collector

RH570 Wireless Data Collector-

Equipped with Ethernet, optical fiber, 4G, 5G, WiFi, Zigbee, and LoRa communication options to adapt to various network environments.

-

Compatible with our single-axis vibration, three-axis vibration, and other wireless monitoring sensors for mixed use, meeting different monitoring needs.

Learn More

New Product Release

New Product Release -

-

RH2000 Online Data Collector

RH2000 Online Data Collector-

Supports 300+ fault characteristic indicators and features black-box storage for edge intelligent alarms and diagnostics.

-

Supports real-time synchronous collection of acceleration, eddy current displacement, motor working conditions, rotational speed, and other data.

Learn More

New Product Release

New Product Release -

-

-

-

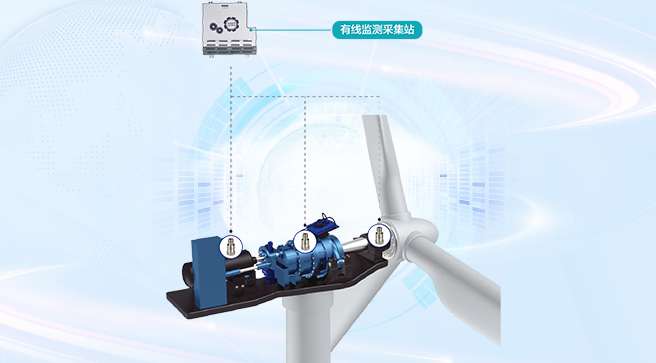

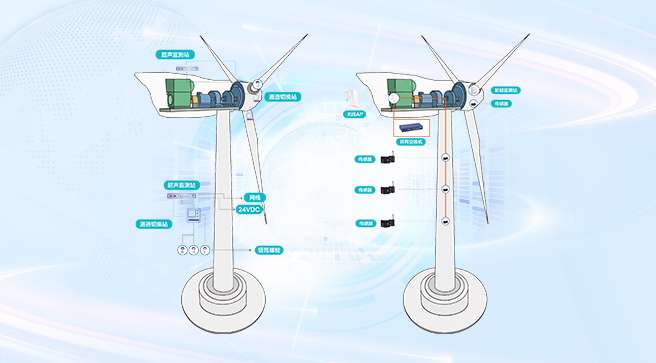

Wind Turbine Transmission Chains

Wind Turbine Transmission ChainsRonds 's wind turbine transmission chains intelligent monitoring solution uses intelligent acceleration sensors to collect vibration data from main bearings, gearboxes, generators and other parts to monitor the operating status of equipment. Through fault diagnosis technology, it evaluates the status of major components of the transmission chain, locates the root cause of the fault, predicts the remaining life of the components, and realizes control of the equipment status.

Learn More

-

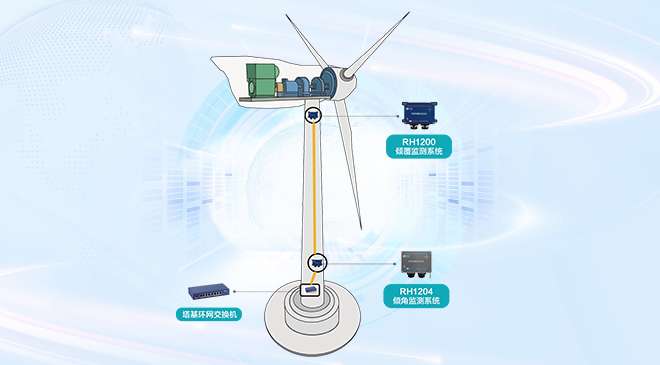

Pitch Bearings

Pitch BearingsRonds 's intelligent monitoring solution for variable pitch bearings effectively solves the three major maintenance pain points and three major monitoring problems of wind turbine variable pitch bearings.

Learn More

-

Wind Turbine Bolt

Wind Turbine Bolt Ronds ' intelligent bolt monitoring solution collects real-time data on the gap displacement of bolt connection flange surfaces and bolt preload force to determine the operating status of bolts, avoid major damage to the unit and damage to power generation caused by bolt loosening and breakage, and provide data support for the safety and reliability of wind turbine operation, ensuring that operation and maintenance personnel can grasp the real-time status of bolt operation in real time and accurately, thereby improving management level.

Learn More

-

Wind Turbine Tower Vibration and Foundation Settlement

Wind Turbine Tower Vibration and Foundation SettlementRonds's tower sway and foundation settlement intelligent monitoring solution collects tower sway inclination, vibration, gyroscope and other data through an intelligent monitoring system to understand the health status of the tower, detect early faults, avoid sudden failures, reduce unplanned downtime, and assist companies in formulating reasonable inspection and maintenance plans to avoid tower collapse and major safety accidents.

Learn More

-

Service Support

As digital transformation deepens, customers at different stages of development have different needs. Ronds adapts to different scenarios to meet customers' needs for digital transformation and development. Ronds Enterprise Services takes the customer journey as the perspective, builds a full-service system, and deeply empowers customers' equipment intelligent operation and maintenance construction.

-

Diagnosis Services

Diagnosis ServicesWith the deepening of digital transformation, the digitalization of various industries is developing in a tiered manner, and customers at different stages of development have differentiated demands, which requires Ronds to have comprehensive service capabilities.

Learn More

-

Talent Empowerment

Talent EmpowermentRonds College of Intelligent Operation and Maintenance of Equipment relies on a strong team of diagnostic analysis experts and intelligent methods. With the aim of "improving equipment reliability and operating efficiency", it designs and develops courses to cultivate practical talents in equipment management in the intelligent era, creates a diagnostic analysis talent training base, and helps customers improve the level of intelligent equipment management.

Learn More

Case Stories

-

Read story

China Huadian Corporation Ltd.

Condition Monitoring for 100+ Wind Farms, Precision Alerts Ensure Stable Operation of Aging Assets

-

Read story

Nanning Power Station

Critical Equipment Monitoring Ensures Safe, Stable, Long-term, Full-load and Optimal Operation

-

Read story

China Datang Corporation Ltd.

Nearly 100 Wind Farms Fully Equipped, Years of Continuous Care Earn Customer Trust

Related News

-

Industry Report

-

-

2023-06-24

Focus on 5G丨Conference of Technology Week and Mobile Information Industrial Chain Innovation

-

2023-02-02

RONDS Signed an Agreement of Deepening Strategic Cooperation with BAOWU Intelligent Equipment Maintenance

-

2022-11-23

Over 100,000 Units丨Equipment Accessed to RONDS Remote Online Monitoring and Diagnosis Center Reach Another Peak

-

2022-09-13

RONDS 2022 Quality Conference —— Customer-centered Quality Construction

-

2022-04-18

RONDS Once Again Joined Hands with the World's Most Competitive Steel Enterprises

-

Start Your Journey to Intelligent Industrial Equipment Maintenance