Case Duration:

May 2021 – Present (2+ Years)

Client Background:

Established by the Shaanxi Provincial Committee of the CPC and Shaanxi Provincial Government to leverage local coal resources, the Group has become: A state-owned mega energy and chemical enterprise; The backbone of Shaanxi's energy-chemical industry; The principal developer of Shaanxi's major coal production bases

Client Requirements & Solutions

Modernizing Equipment Monitoring for Intelligent Mining

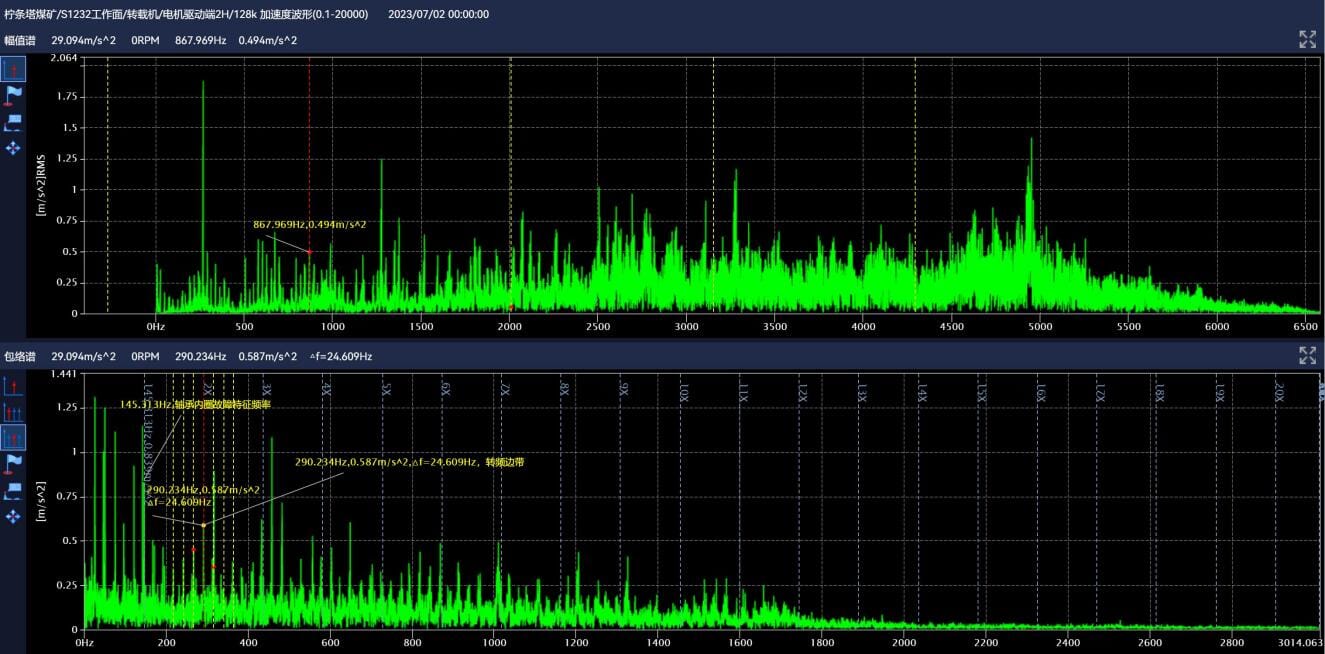

Real-Time Diagnostics & Precise Fault Identification:

To address limited existing monitoring capabilities, RONDS:

1. Deployed 1,000+ monitoring points across 160+ critical assets at Ningtiaota Mine and Huangling No.1 Mine, including:

1) Conveyors

2) Pump houses

3) Air compressors

4) Main ventilation fans

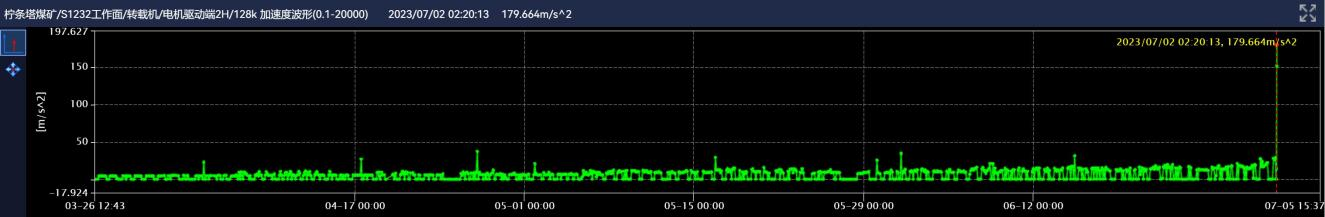

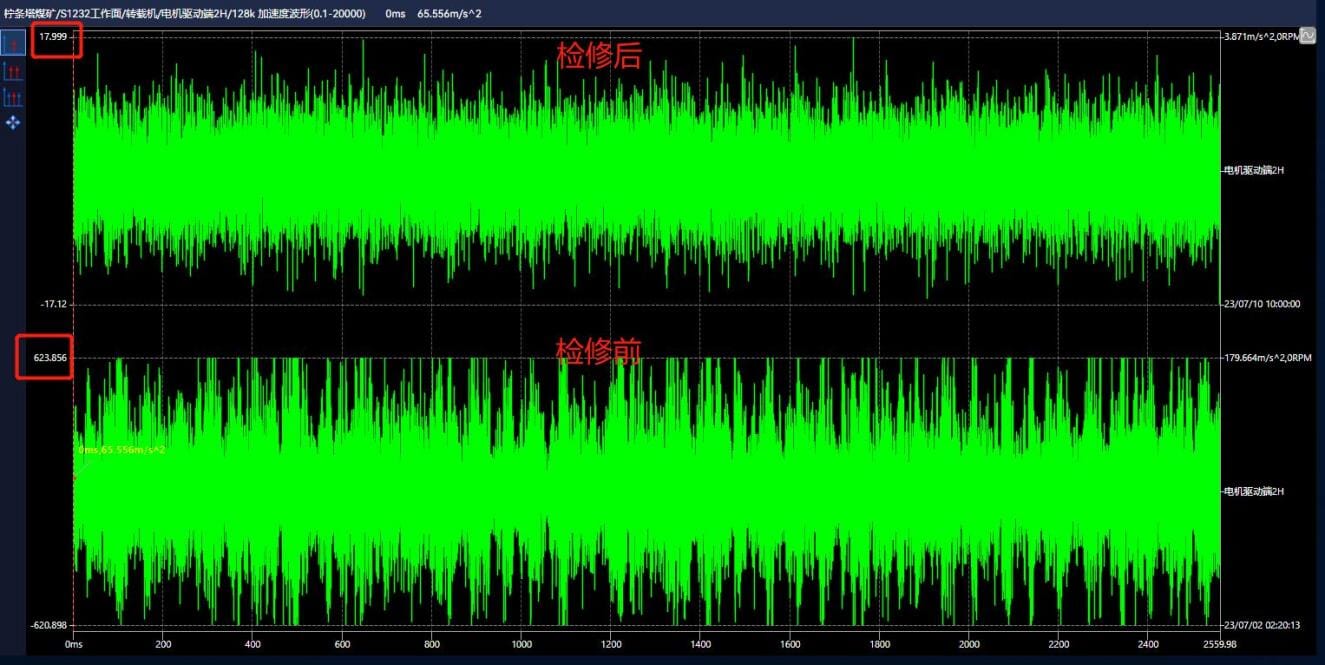

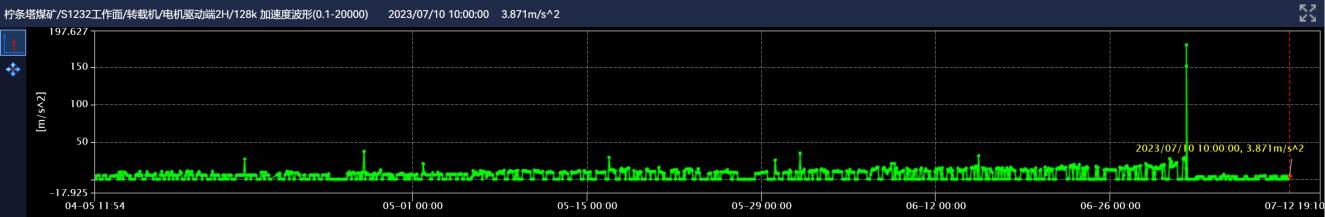

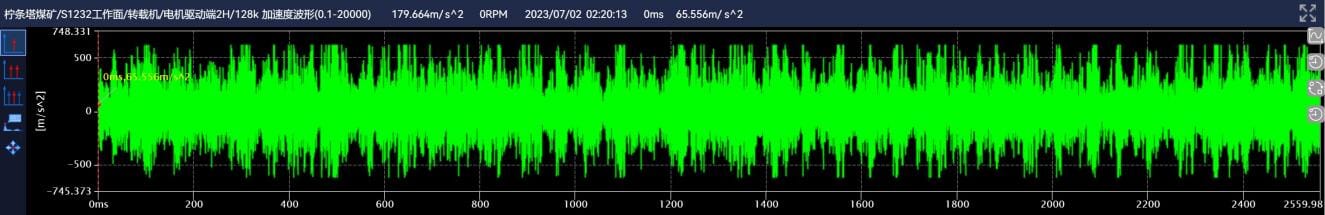

2. Enabled real-time anomaly detection

3. Achieved precise fault location and degradation assessment

Critical Equipment Monitoring for Uninterrupted Production:

Implemented monitoring for fully-mechanized mining face equipment:

1. Transport machines

2. Crushers

3. Transfer devices

4. Entry belt conveyors

Application Value

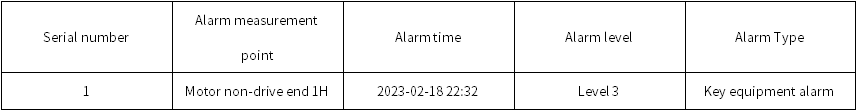

Ensuring Safe Mine Production:

By integrating critical equipment into RONDS' remote monitoring system, we have:

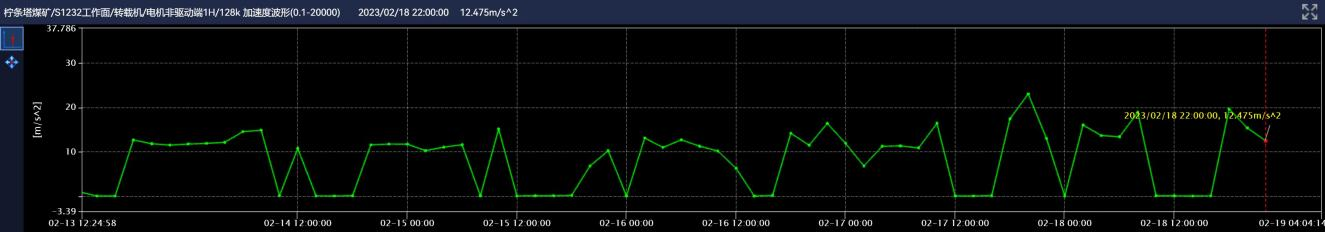

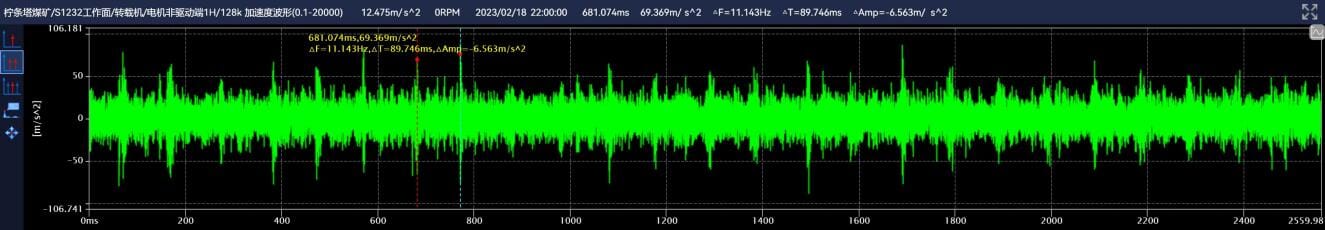

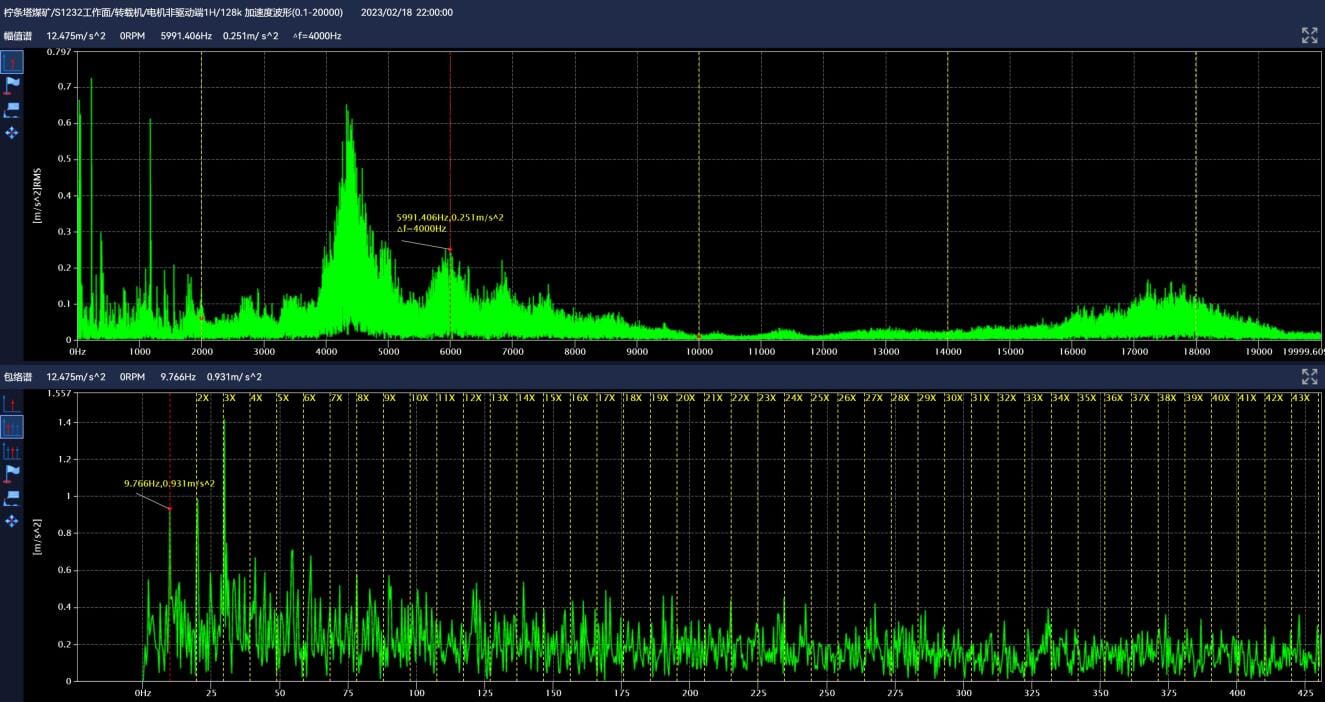

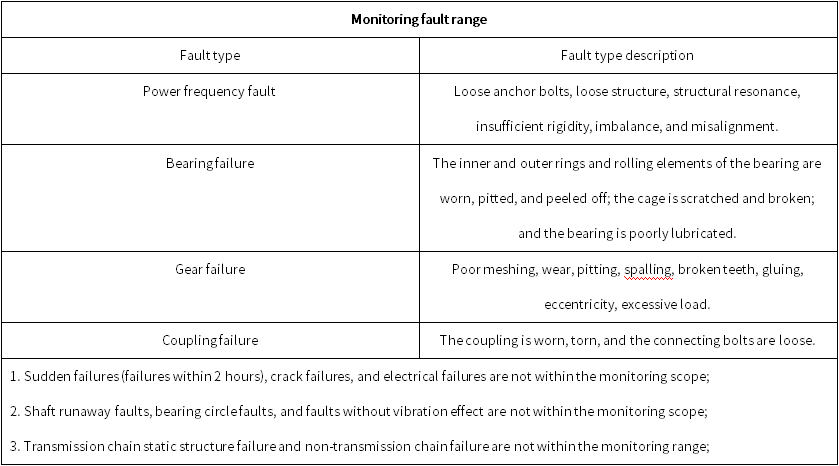

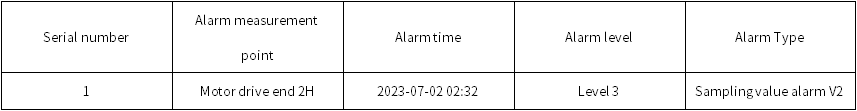

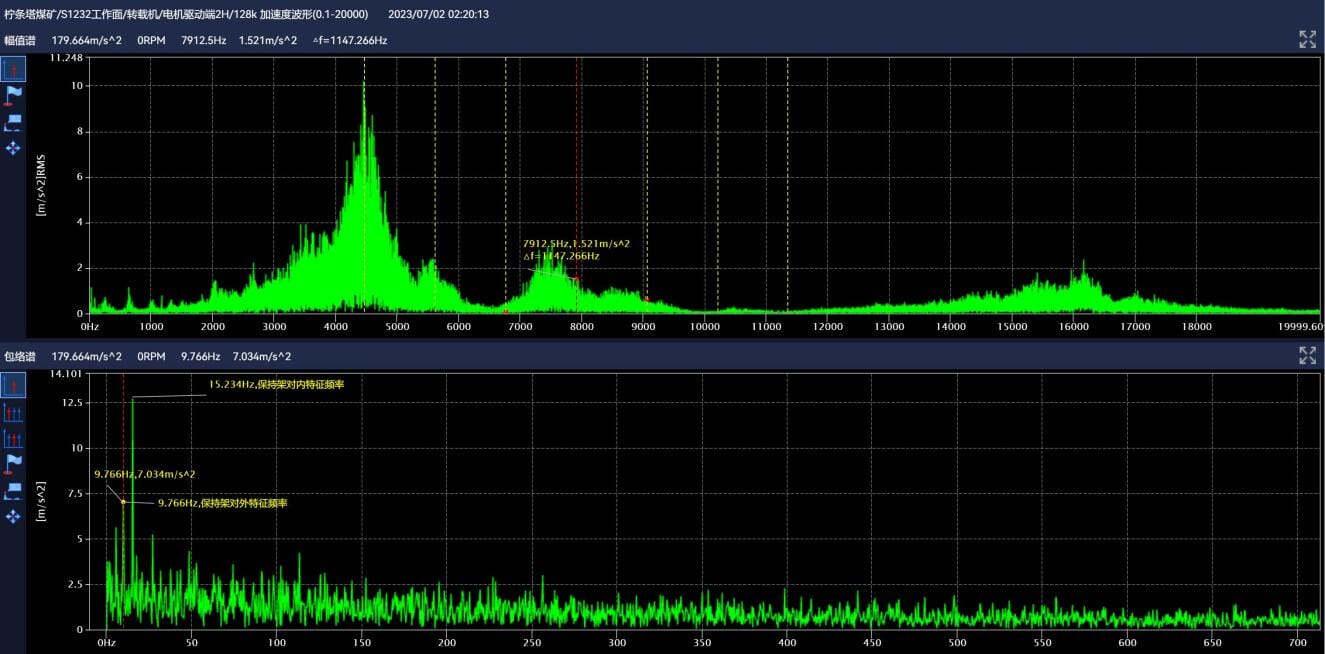

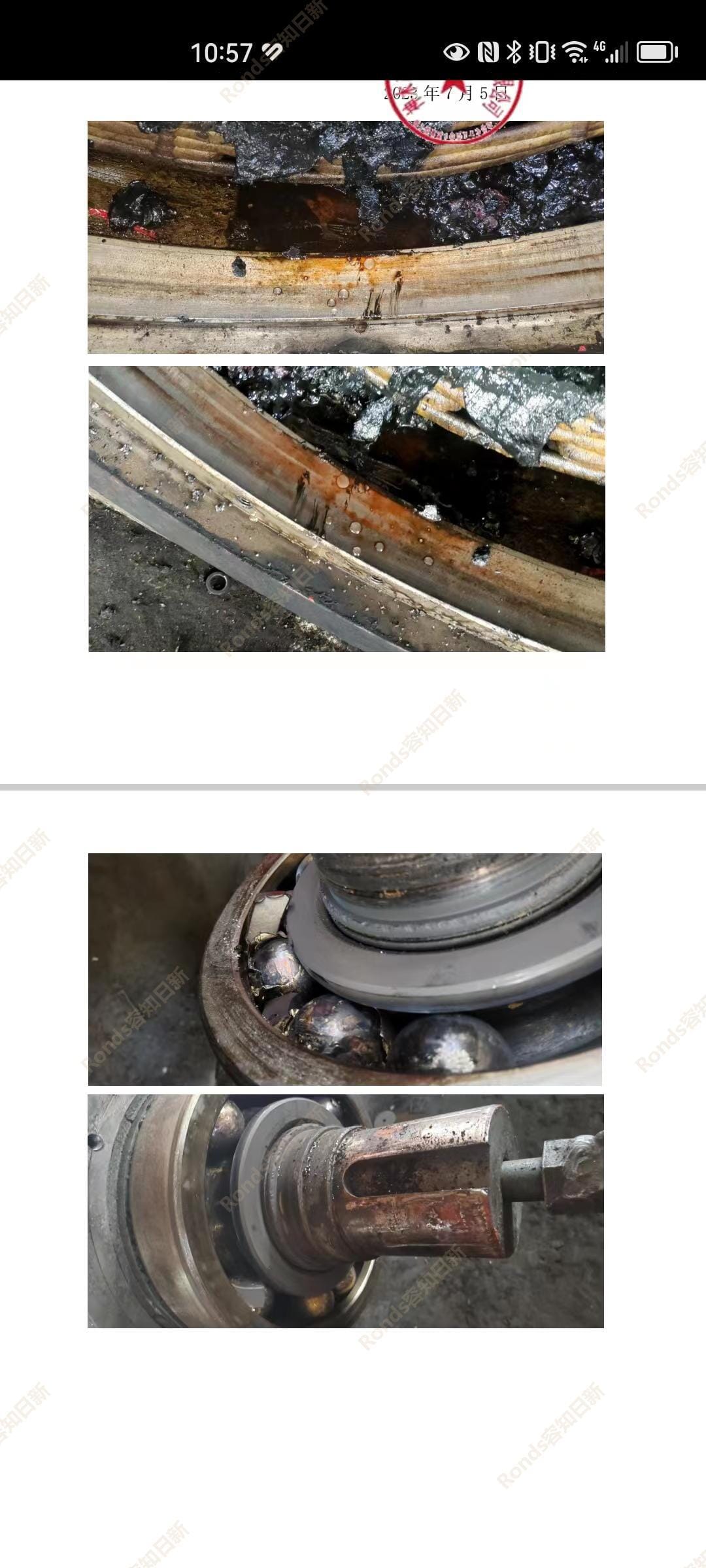

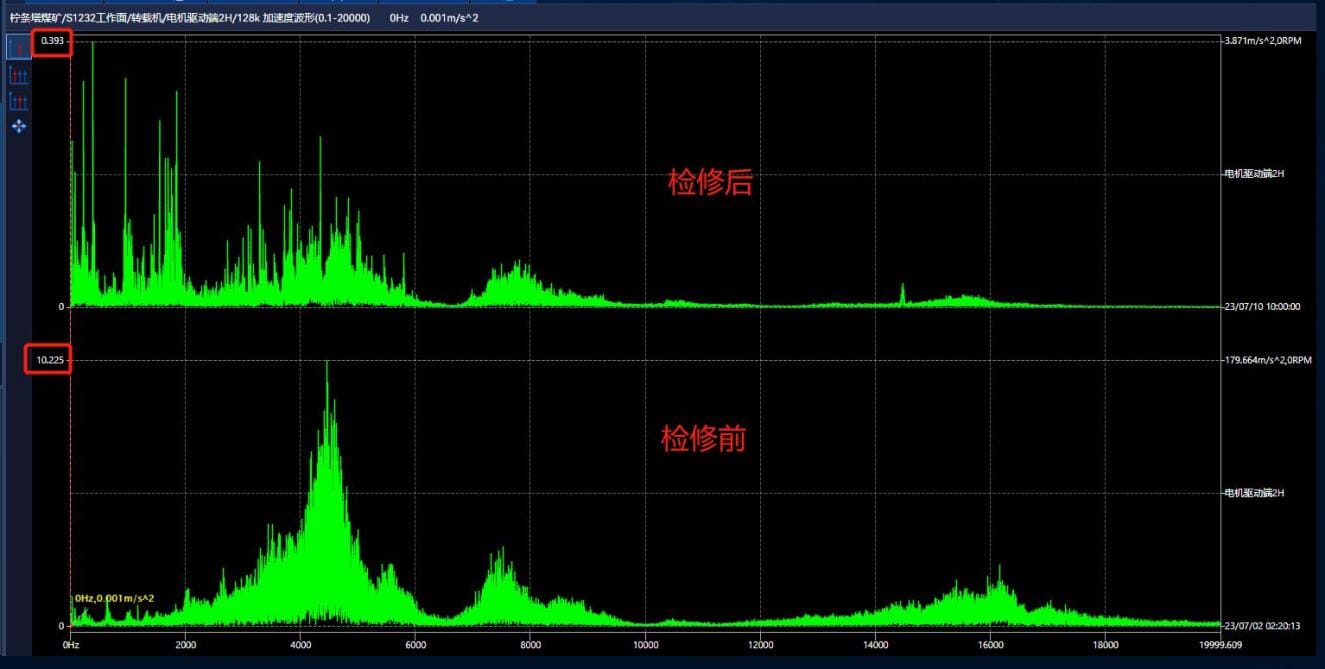

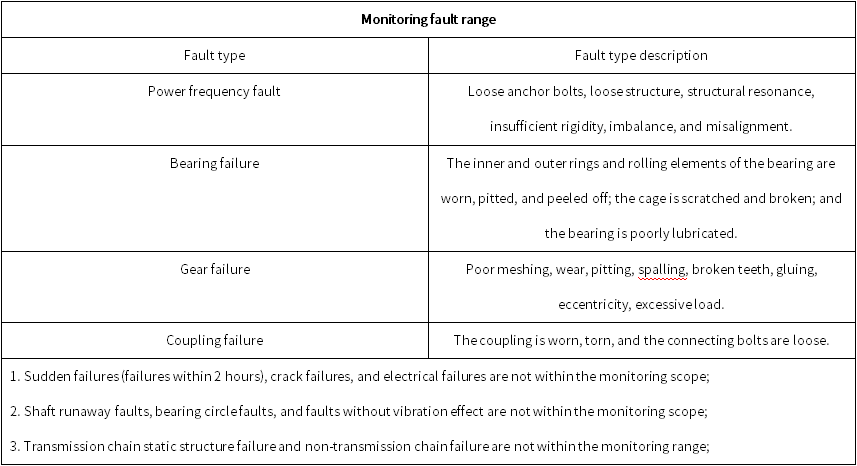

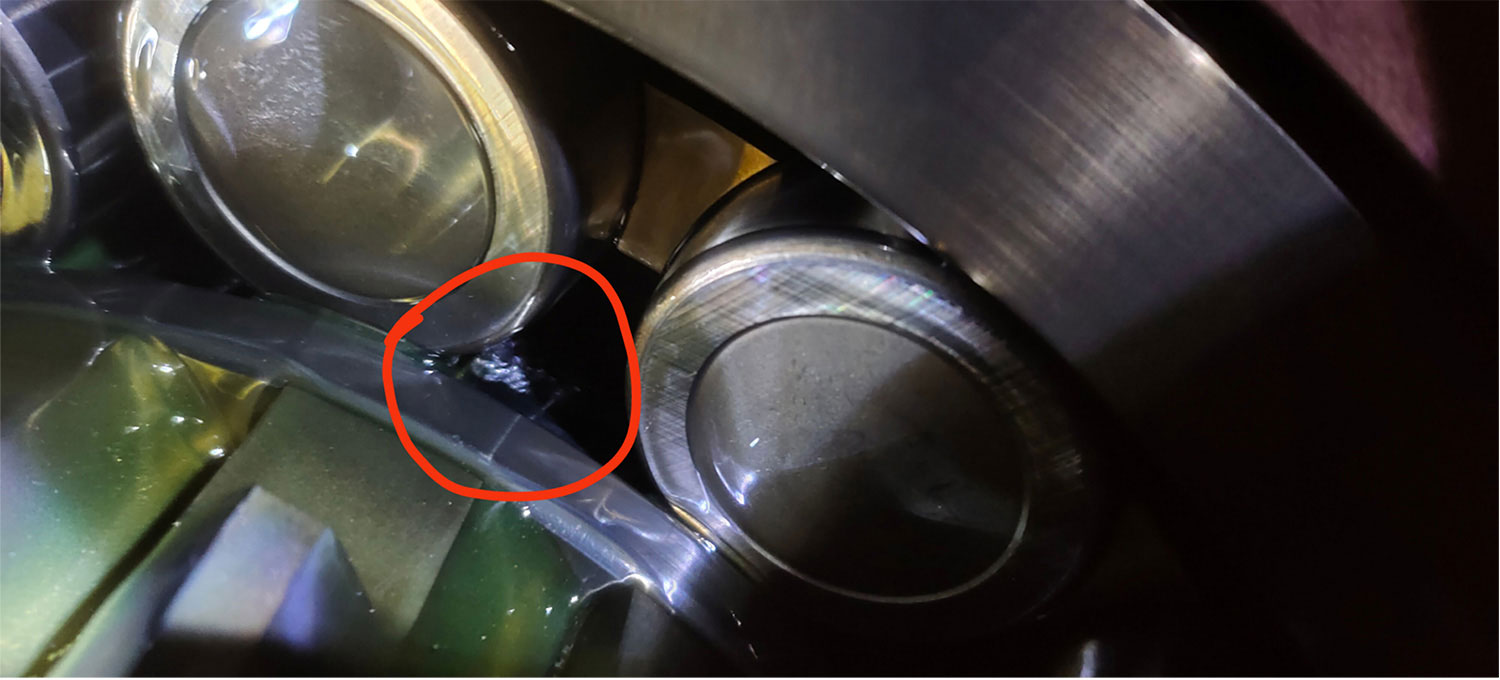

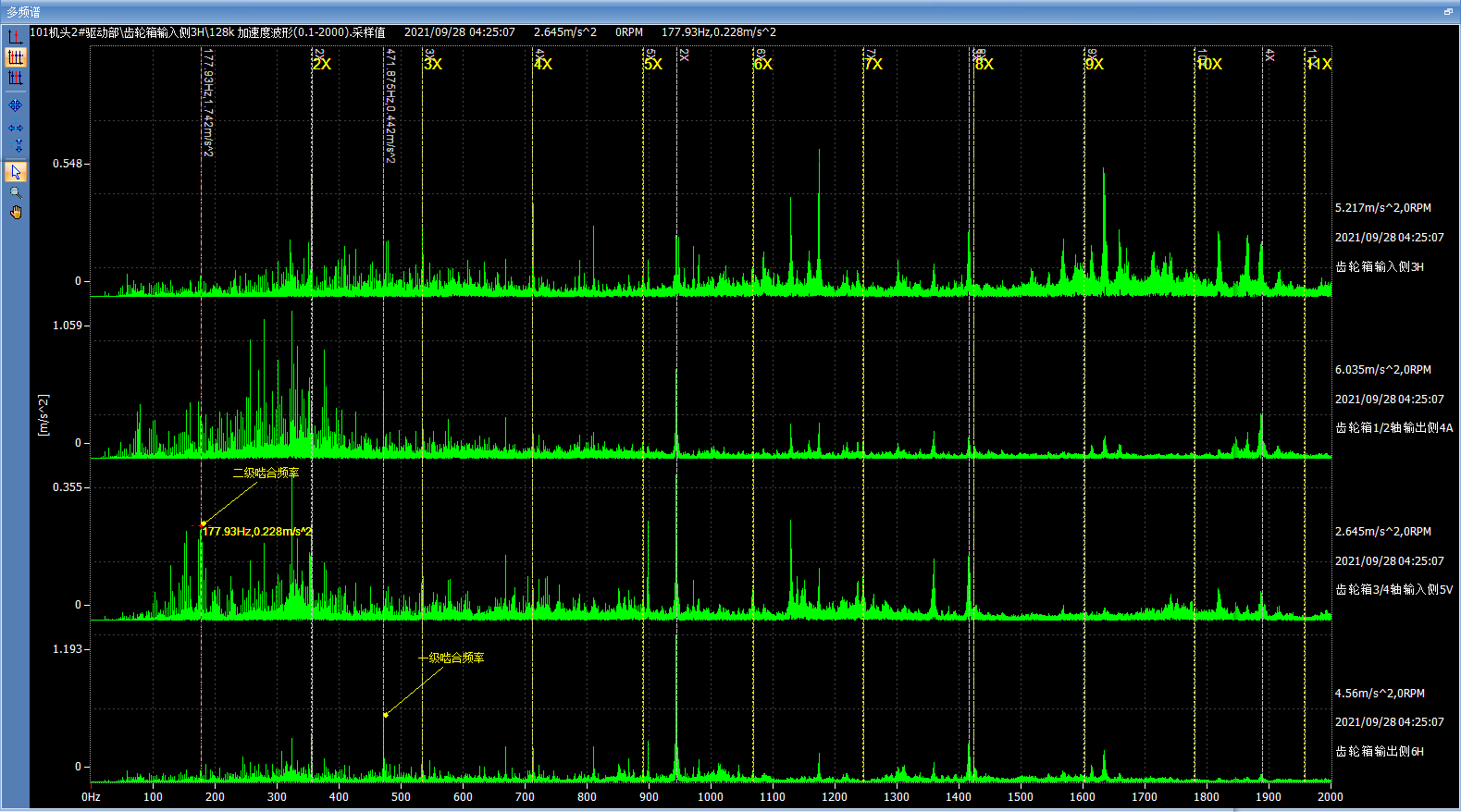

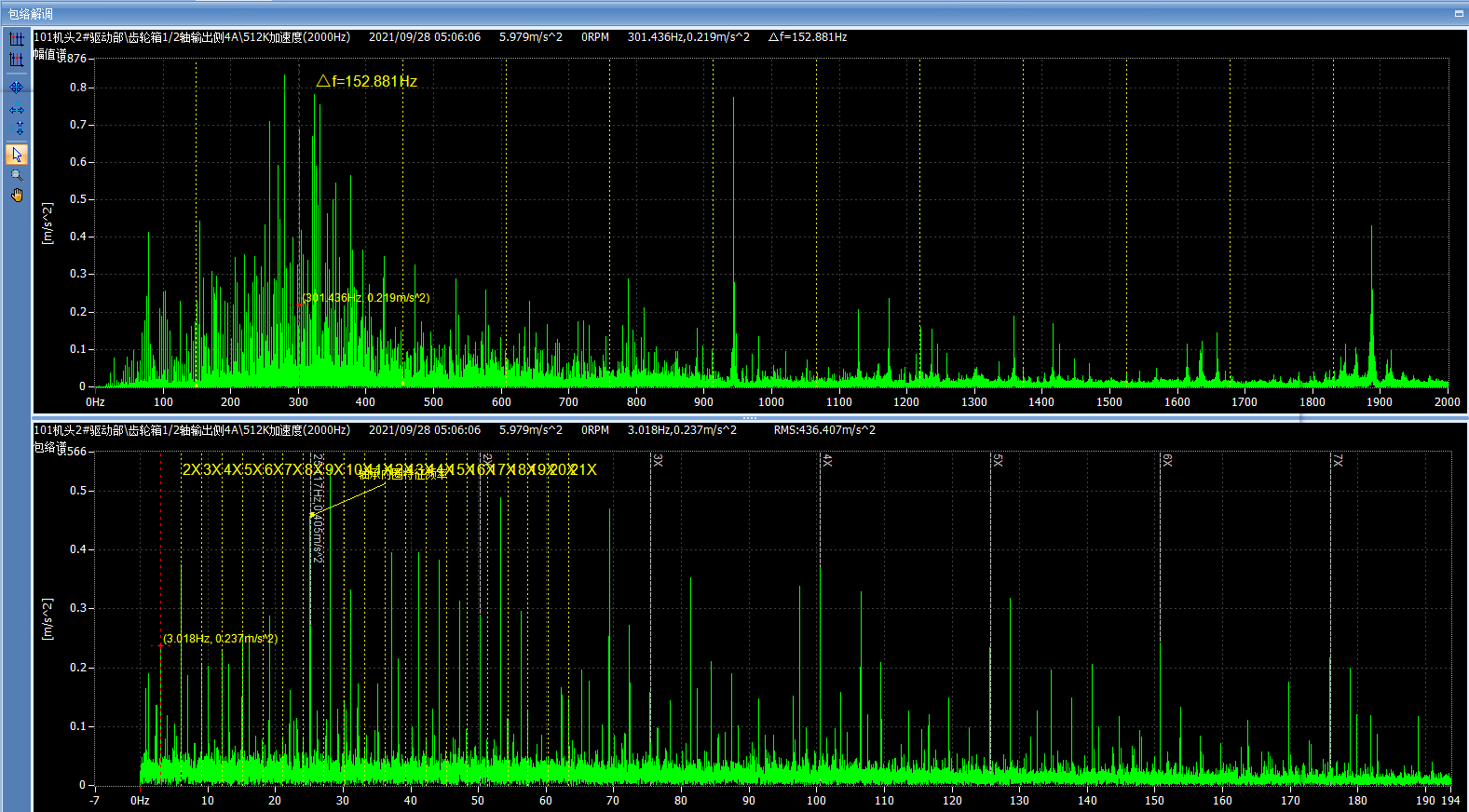

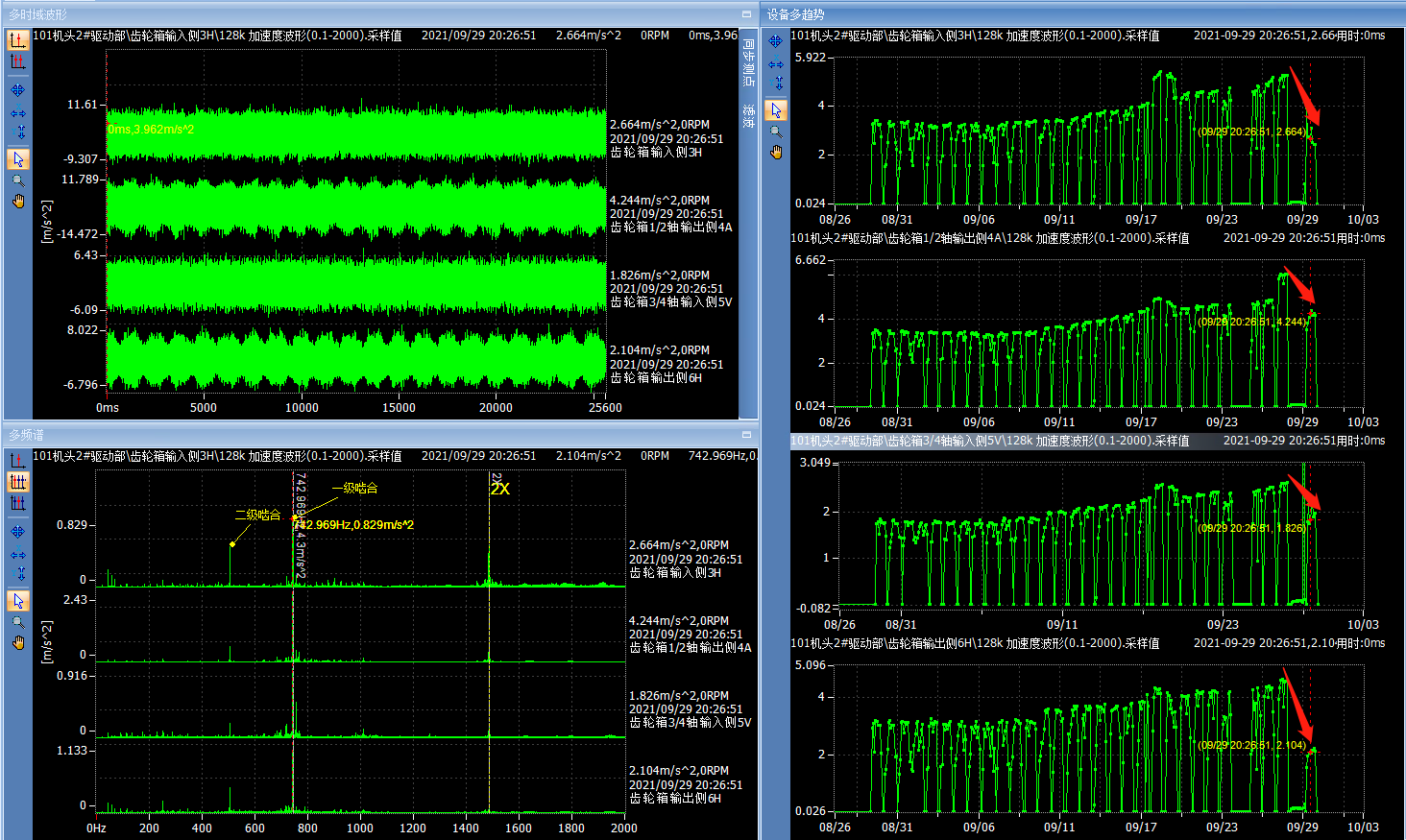

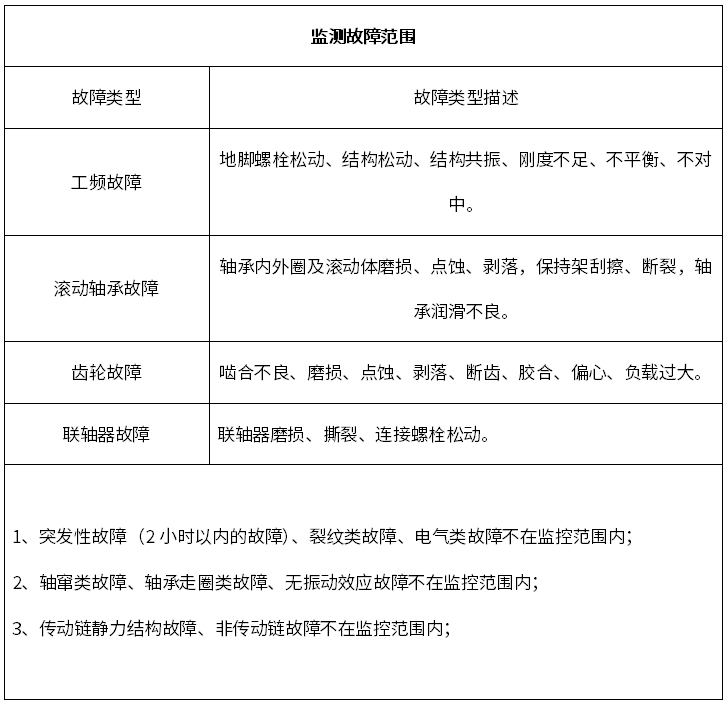

1. Successfully closed multiple equipment failure cases including:

1) Bearing failures

2) Gear defects

3) Lubrication issues

4) Power frequency abnormalities

2. Effectively prevented unplanned shutdowns and potential accidents

3. Achieved safety compliance during monitoring period

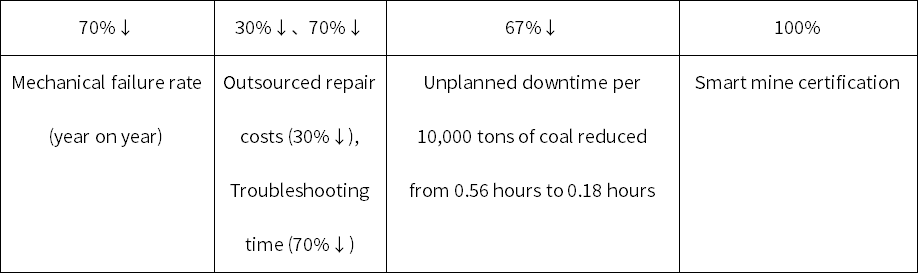

Efficiency Gains & Sustainable Production:

1. Enhanced Equipment Control

1) Improved availability

2) Increased reliability

3) Maintainability optimization

2. Economic & Environmental Benefits

1) Prevented production losses

2) Reduced safety/environmental risks

Equipment Data Accumulation and Refinement of Intelligent Algorithms Facilitate Smarter Monitoring Systems:

Through the combined application of intelligent algorithms and expert diagnostic analysis, the customer has achieved real-time operational status assessment and future state prediction for key coal mining equipment.

Success Cases

-

Shaanxi Coal Industry Ningtiaota Coal Mine Transfer Machine

Shaanxi Coal Industry Ningtiaota Coal Mine Transfer MachineLearn More

-

Shaanxi Coal Industry Ningtiaota Coal Mine Transfer Machine

Shaanxi Coal Industry Ningtiaota Coal Mine Transfer MachineLearn More

-

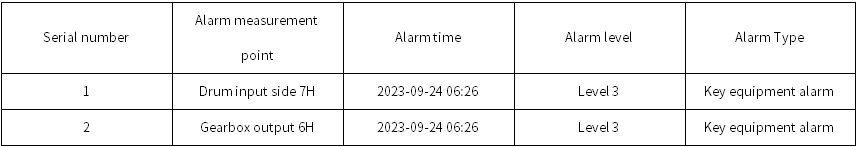

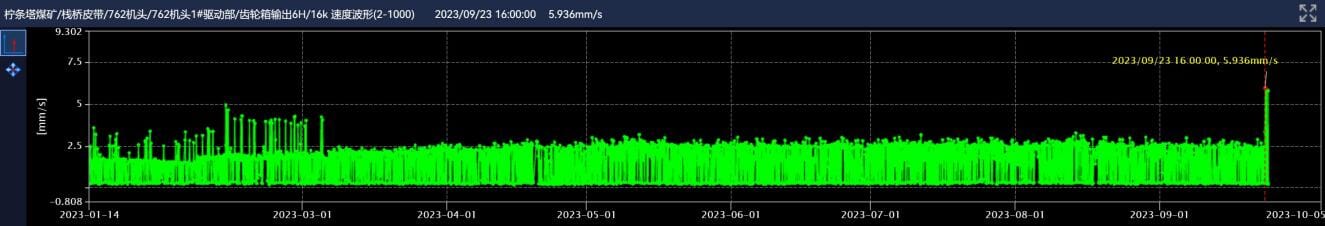

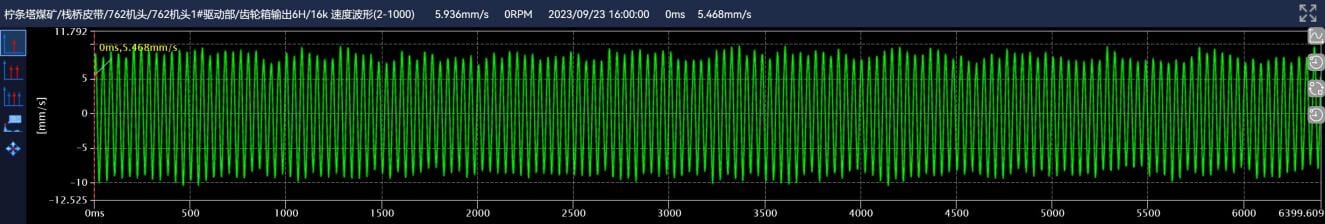

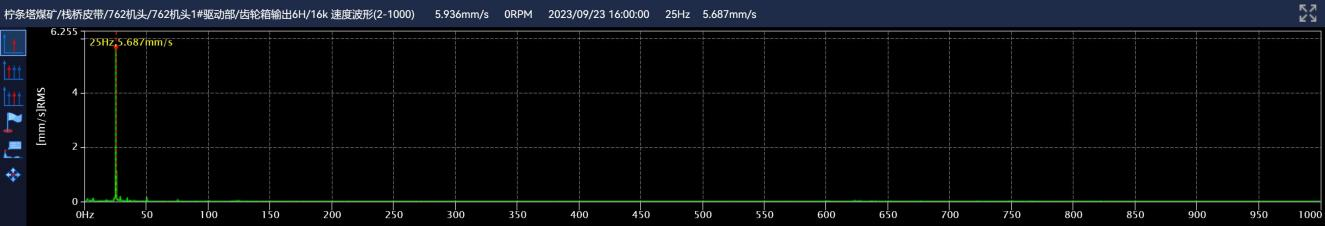

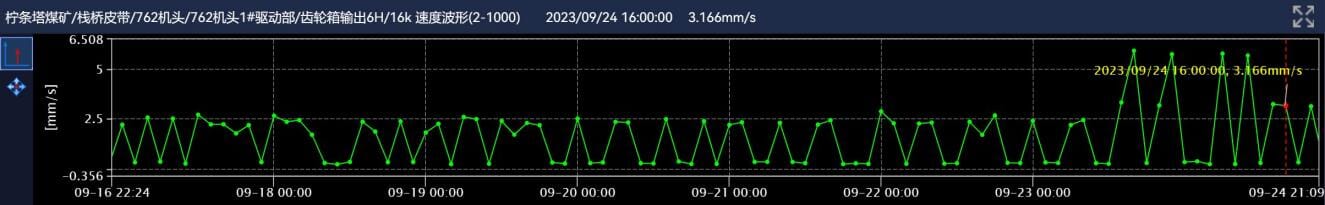

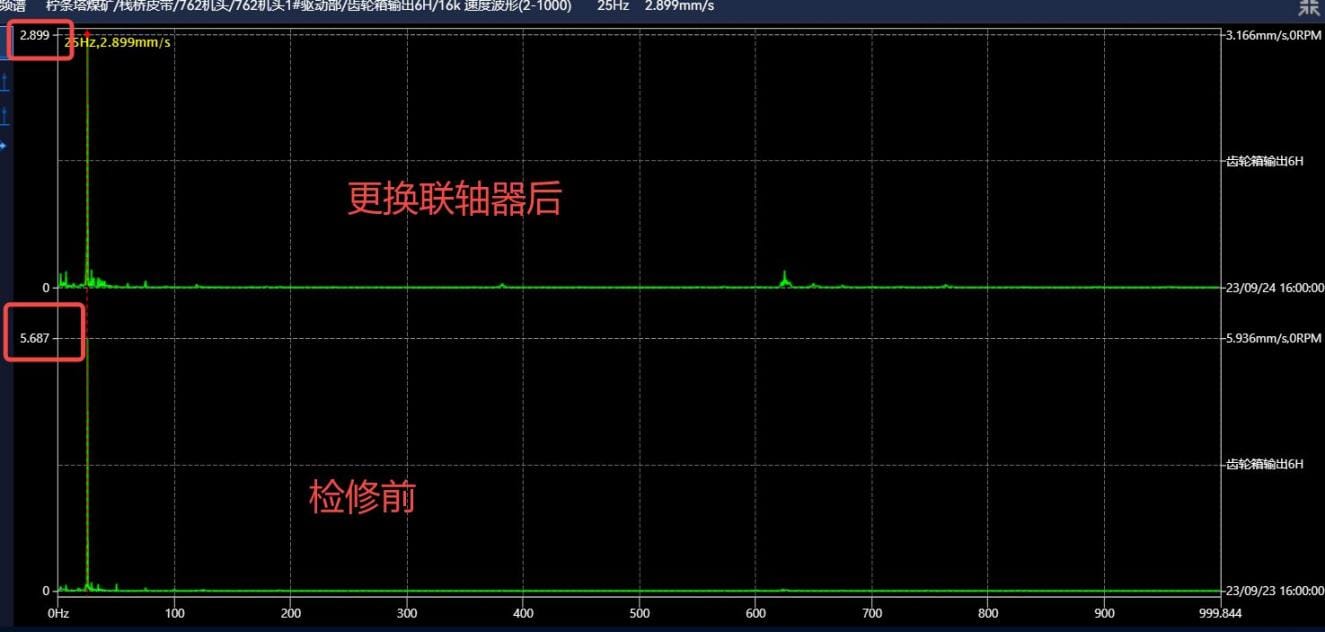

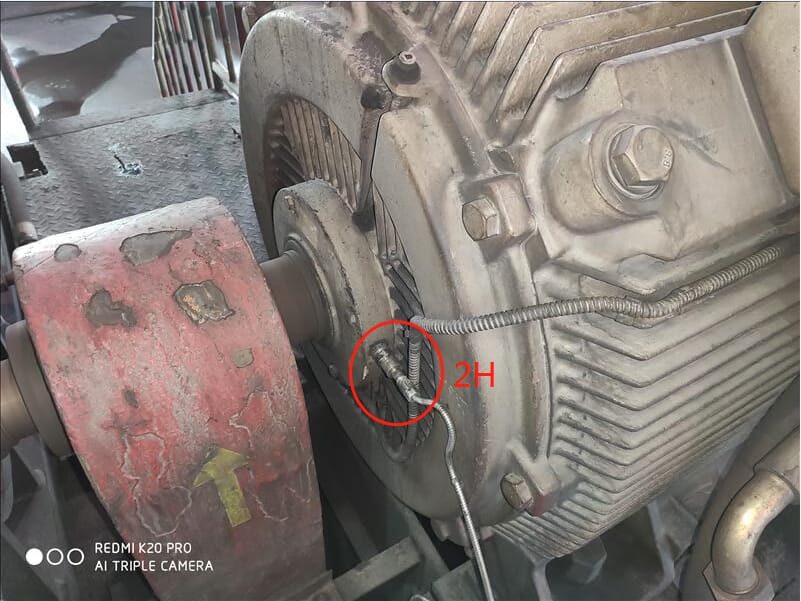

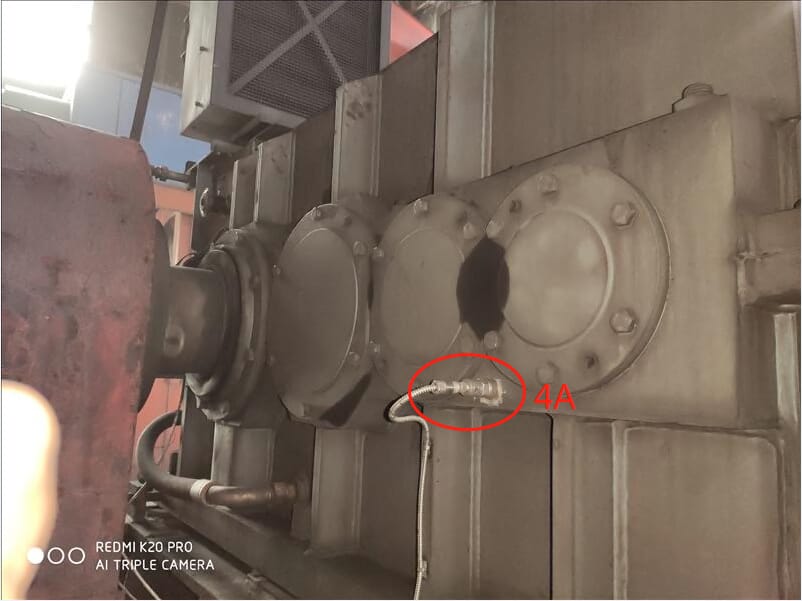

Shaanxi Coal Industry Ningtiaota Coal Mine 762 head 1# drive unit

Shaanxi Coal Industry Ningtiaota Coal Mine 762 head 1# drive unitLearn More

-

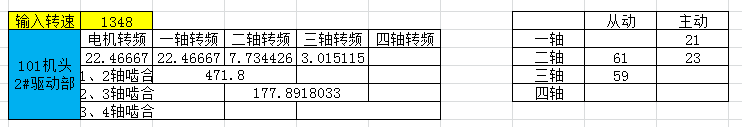

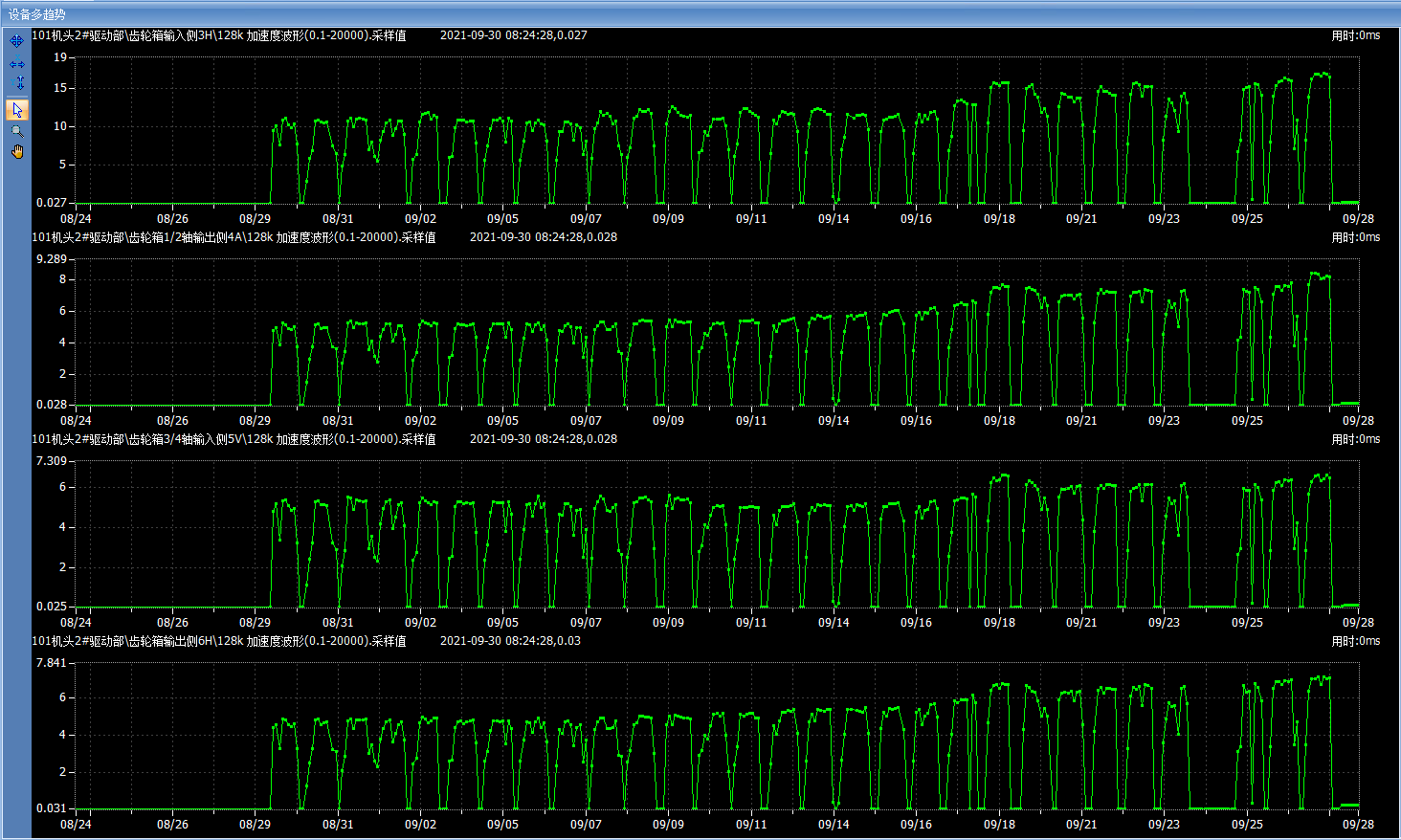

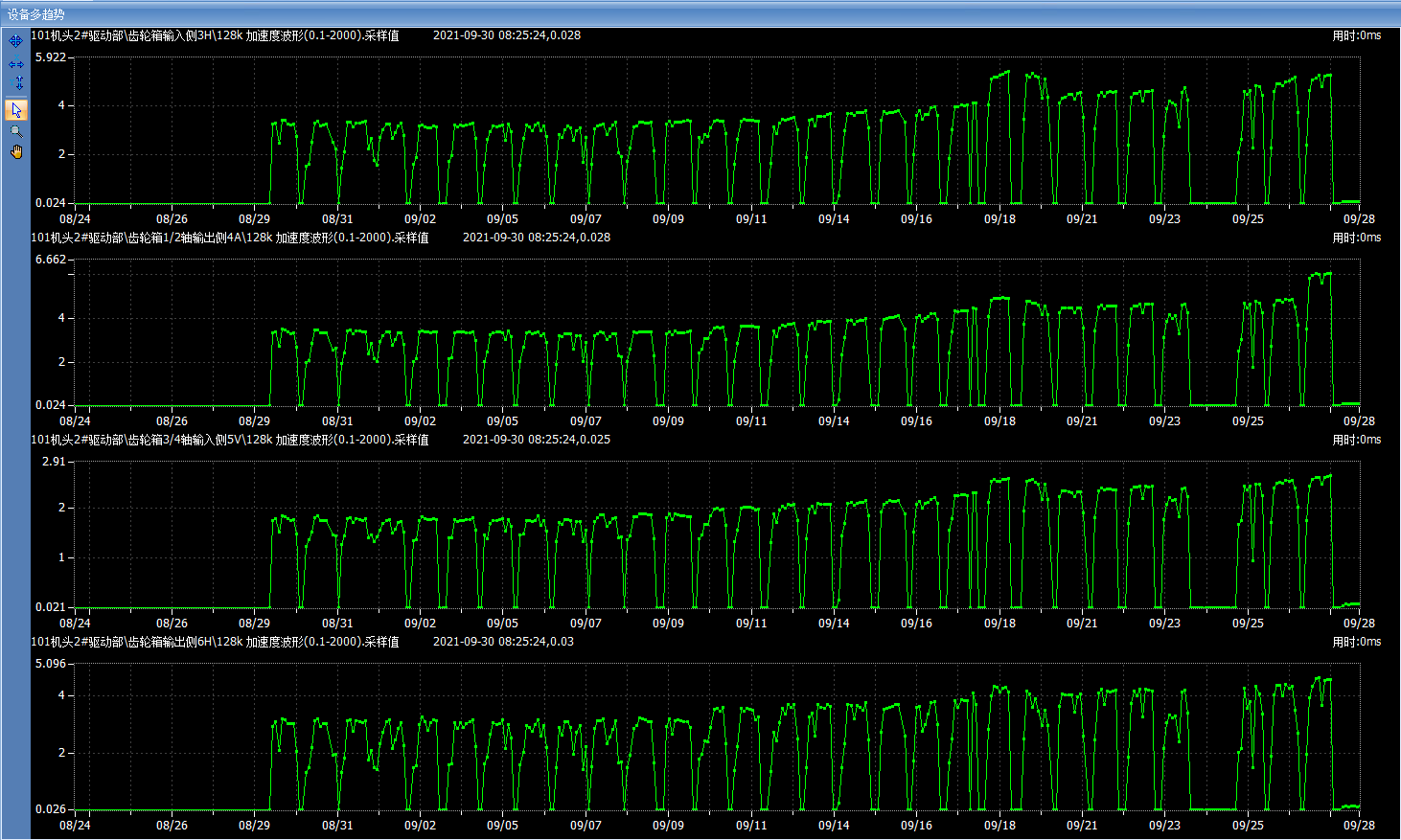

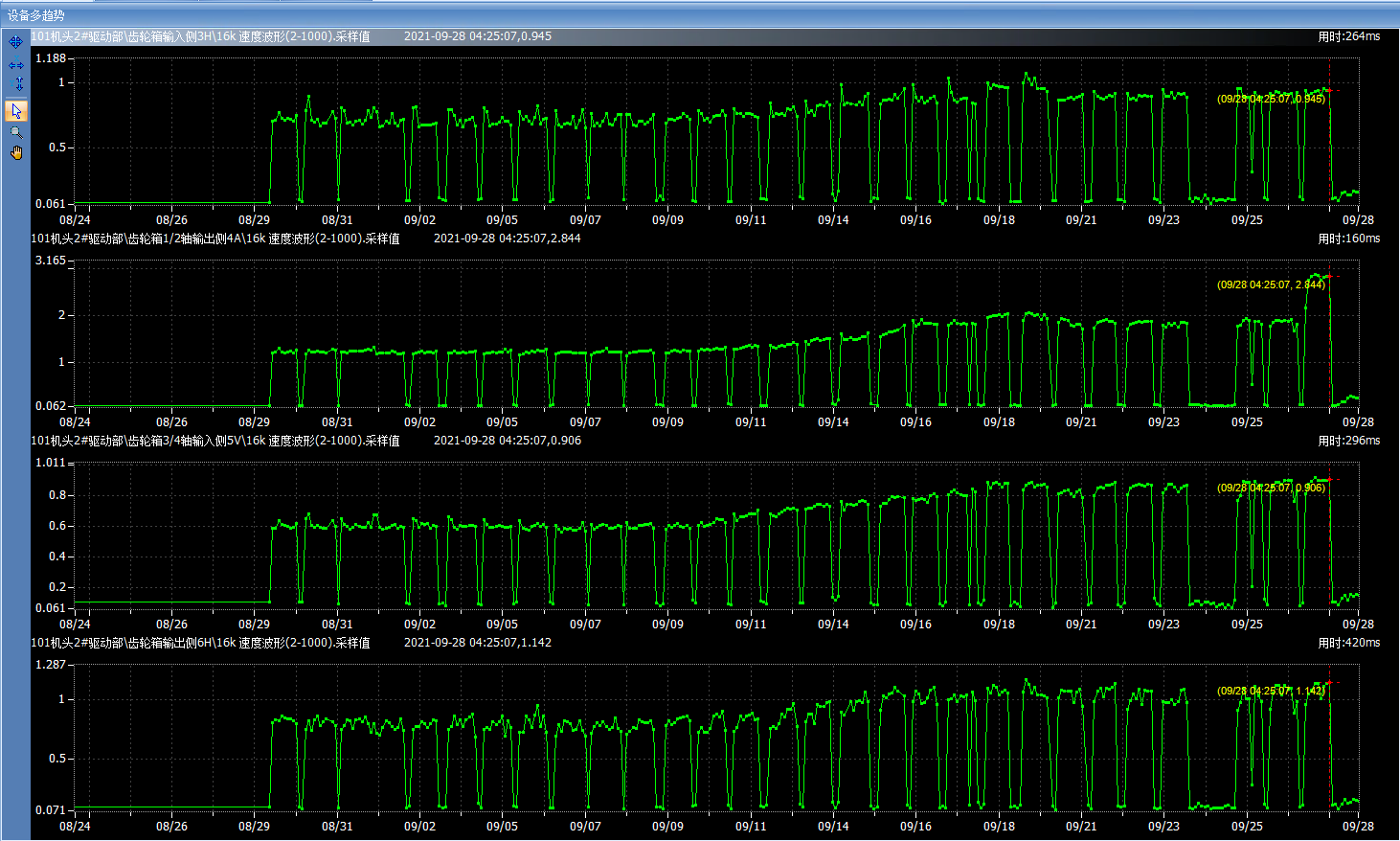

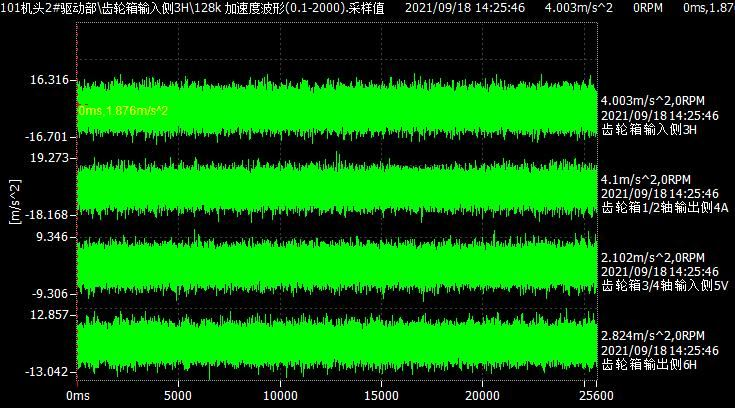

陕西煤业柠条塔煤矿振动状态监测_101机头_101机头2#驱动部_验证报告_1

陕西煤业柠条塔煤矿振动状态监测_101机头_101机头2#驱动部_验证报告_1Learn More

Start Your Journey to Intelligent Industrial Equipment Maintenance